Sustainable production of bamboo at MOSO®

A sustainable production of bamboo at MOSO is something that we are...

The High Density® bamboo production process includes all the steps to create a material that is harder, stronger and more durable than almost any wood, and an attractive natural alternative to many non-renewable materials. The material is produced from bamboo strips (fibres), which are compressed into beams or panels as a base material for many products. Compared to standard strand woven bamboo, High Density® is far more stable and environmentally friendly. Below we explain how bamboo flooring, beams and boards are produced from hollow bamboo stems, to reach the highest quality products:

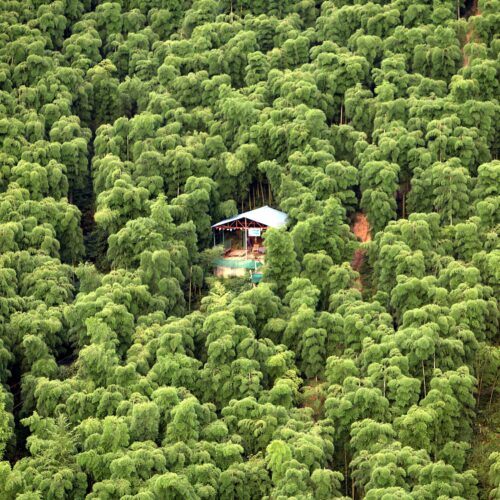

Making use of the best base material will result in the best final product. Endless forests in Eastern-Chinese mountainous regions are covered with bamboo. Bamboo stems have an optimum age when talking about MOSO® bamboo products: ideally, the stems are harvested when they are 5 years old. Younger stems are not fully lignified and, therefore, the material will not have the right density and is not hard enough. Older stems turn grey, resulting in unattractive stains in final products. The quality of the bamboo stems can be partly determined during purchasing, but this is difficult to see in the new final product as the bamboo can still behave in an unexpected way later on when low quality stems have been used. MOSO® bamboo products are made of the best base material, which is checked by our own team, before production is started.

Freshly harvested bamboo stems are cut into strips, and this production process consists of more than just slicing the hollow bamboo stem into pieces. When removing the skin, bamboo material is also lost, which is considered waste that can be used as biomass for energy production. The more bamboo that is removed and turned into biomass, the more expensive the remaining strip becomes meaning the best bamboo strips have no skin left, thus are the most expensive strips. When determining the quality of the strips, it is the purchasing phase that is of importance, but you will not directly see the difference in the final product. MOSO® only accepts high quality strips for its bamboo products and MOSO® staff check the strips before production is started.

The bamboo strips are crushed to open up the material for further processing and become bundles of bamboo fibres, called strands. This process and quality of the crushing will determine the quality of the glue impregnation and bonding in the next production steps. A better crushing of the strands requires more precise processing, and therefore higher costs. MOSO® staff checks the strands before production is started.

MOSO® High Density® bamboo products are available in three standard colours: Natural, Caramel and Chocolate. Natural is the colour of the material without thermal treatment. When the bamboo strands are steamed, they become darker and more brownish: Caramel. With a thermal treatment of ca. 200°C the colour changes into a dark brown Chocolate. The treatment alters the material: the sugar component of the bamboo is caramelised or broken down, making the material more durable and stable. This treatment can be executed at various temperatures for a shorter or longer time. Lower temperatures and shorter times usually result in lower costs, a preferred option for some manufacturers. MOSO® always focuses on the optimal durability and stability of the final bamboo product and ensures the best treatment of the materials.

Crushed bamboo strands are glued and compressed to bond the bamboo fibres together. MOSO® aims to replace chemical resins with bio-glues. However, the quality of the final products is most important to MOSO®, meaning this is not possible yet. So far, no bio-glue can match the high MOSO® quality requirements. Until bio-glues can be used in production without compromising quality, glue from respectable brands is used, ensuring the lowest emissions and best bonding. The type and amount of glue applied during the production is very hard to determine once the final product is manufactured. Nevertheless, this is one of the key differences between High Density® and regular Strand Woven Bamboo. Glue costs are significant in the total production costs. Many factories make their own glue or use glue from a local supplier to reduce such costs, while MOSO® chooses to work with respectable brands like Dynea.

Depending on the type of product, dimensions, and required colour of bamboo, compression can be done in cold-press or hot-press systems. Each type of glue needs a certain temperature during compression to cure. Additionally, the way bamboo strands are placed in the molds has an effect on the stability and look of the final product. Well-trained MOSO® quality controllers test the material after this important production step to ensure the quality of the final product. It is hardly possible to do this without laboratory tests.

Bamboo, like any other natural material, is affected by moisture: it expands when its moisture content increases and contracts when its moisture content decreases. It is crucial that, within each production step, the moisture content is lowered and controlled in drying rooms. The moisture content of the final product, supplied from the factory, determines significantly the way bamboo products behave after installation. A large difference in moisture content can create big problems. As an example: when installing a product with a too high moisture content in a dry area, the bamboo product will shrink because the moisture content decreases in the new situation. To ensure the high quality of the final bamboo products, MOSO® quality inspectors keep track of the moisture content during and after production of each production batch.

Since Strand Woven Bamboo or High Density® Bamboo are very dense and hard, it is difficult to determine the moisture content of the final product. Through continuous product development during the last 10 years, MOSO® has mastered the method to control the moisture content of each final product. To ensure the high quality of the bamboo products in their final application, local MOSO® quality inspectors monitor the moisture content during and after production of each production batch.

The last step in the High Density® bamboo production is the final profiling of the material. A material as hard and dense as High Density® bamboo requires a lot from the tools used for profiling. By using high quality, often European made machines, MOSO® ensures the right way of processing the material into final products. A good example is the way click systems are profiled into the material. The best machines create the best surface finishing. Depending on the product, MOSO® uses High Density® bamboo as a top layer for panels and flooring, or as solid beams or flooring.

Discover just a few of the many High Density® bamboo products available at MOSO®

A sustainable production of bamboo at MOSO is something that we are...

What is important to think about when looking at different decking types?

Discover everything about MOSO® Bamboo Products and why bamboo is the building...